Henan Ruishi Renewable Resources Group Co., Ltd.

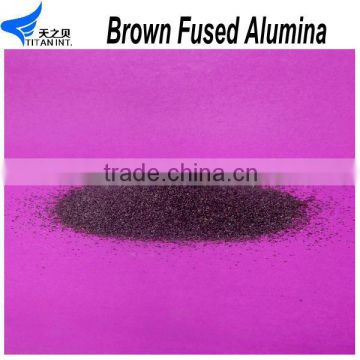

Main Products: Corundum Brown Fused Alumina, White Fused Alumina, Vice-white Fused Alumina, Mullite, Tabular Alumina, Calcium Aluminate, Ferrite Calcium Aluminate, Calcined Flint, Calcined Bauxite

Home > Company Introduction

Company Overview

Henan Ruishi Investment Group Co., Ltd. (short for Ruishi Group), formerly known as the Henan Yichuan Ruishi Abrasive Co., Ltd., founded in 1992, mainly produces all kinds of abrasive materials, special refractory materials and metallurgical accessories. After nearly 20 years of rapid development, Ruishi Group develops into a corporate enterprise including 7 wholly-owned subsidiaries such as bauxite calcination plant, smelting plant, sand plant, new energy plant, solar line cutting plant, renewable resources company and international trade company. Ruishi Group, with self-import and export rights, is one of the 100 largest export bases in Henan Province, which covers an area of 300 thousand square meters and has 350 employees. Ruishi Group has 6 sets of China first-class large-scale production equipment 3 600 KVA/360 KVA high temperature smelting furnaces and 6 automatic Barmac production lines. To ensure the material stability, Ruishi Group built 4 sets of the shaft kilns, to produce high quality bauxite blocks for its own.

Ruishi Group passes the ISO 9001:2000 International Quality System Certification, and its products are exported to more than 20 countries and regions such as the United States, Russia, Japan and South Korea.

R&D on New Products

From 2010, Ruishi Group began to research and develop fused corundum composite using industrial solid waste. The products were developed successfully in 2012. The products are manufactured by new refractories smelting technology, and are featured with low cost, no pollution, high resources comprehensive utilization rate, and broad market foreground.

In 2011, Ruishi Group purchased 267 thousand square meters of land and found Ruyang Gold Diamond Regenerated Resources Technology Co., Ltd. to develop energy-saving and environmental-friendly industries.

In 2012, Sapphire LED Backing Materials Project with annual capacity of 5 million pieces of Ruishi Group was registered in Luoyang Development and Reform Commission. The trial workshop of sapphire will be put into production in Oct. 2012. It forecasts that the annual production value will reach about CNY 1 billion.

Future Prospect

Besides the construction of production base, in 2012, Ruishi Group invested CNY 10 million to build the headquarters in Floor 23, Wuzhou Mansion, Luoyang. It will strengthen worldwide sales net and support services, and will increase the sales effect by 50%.

In the future, Ruishi Group will focus on the short of mineral resources and power crisis, invest green, environmental-friendly, energy-saving and high efficiency innovation fields, research and develop new materials and powers, cut resources consumption and environment pollution, and promote the rapid development of local economy and refractories industry.

-

Manufacturer, Trading CompanyBusiness Type

-

1998Year Established

-

50,000-100,000 square metersFactory Size

-

101 - 200 PeopleTotal Employees

Company Detail

Transparency is the foundation of our partnership. Below is a comprehensive overview of our operational metrics, from business scale to global market reach, giving you a clear picture of our capabilities.

-

101 - 200 People Total Employees

-

Domestic Market, Eastern Asia, Western Europe, North America, Eastern Europe, Southern Europe, Mid East, South Asia, Southeast Asia, South America, Central America Main Markets

-

Tianjing, Dalian, Shanghai Port of Shipment

-

Black Metal & Products Main Industry

Our Certifications

Showcasing our professional qualifications and recognized industry certifications.